Panama Canal

Did you know...

The articles in this Schools selection have been arranged by curriculum topic thanks to SOS Children volunteers. Click here to find out about child sponsorship.

| The Panama Canal | |

|---|---|

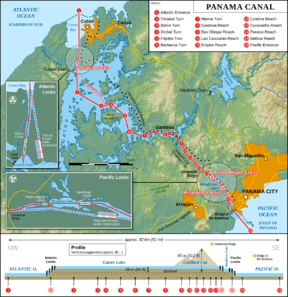

| A schematic of the Panama Canal, illustrating the sequence of locks and passages | |

| Original owner | La Société internationale du Canal |

| Principal engineer | John Findlay Wallace, John Frank Stevens (1906–1908), George Washington Goethals |

| Date of first use | on August 15, 1914 |

| Locks | 3 locks up, 3 down per transit; all two lanes

|

| Status | Open, extension in process |

| Navigation authority | Panama Canal Authority |

The Panama Canal (Spanish: Canal de Panamá) is a 48-mile (77.1 km) ship canal in Panama that connects the Atlantic Ocean (via the Caribbean Sea) to the Pacific Ocean. The canal cuts across the Isthmus of Panama and is a key conduit for international maritime trade. There are locks at each end to lift ships up to Gatun Lake (85 feet (26 m) above sea-level). Gatun Lake was created to reduce the amount of work required for the canal. The current locks are 110 feet (33.5 m) wide. A third, wider lane of locks is being built.

France began work on the canal in 1881, but had to stop because of engineering problems and high mortality due to disease. The United States (US) later took over the project and took a decade to complete the canal in 1914, enabling ships to avoid the lengthy Cape Horn route around the southernmost tip of South America (via the Drake Passage) or to navigate the Strait of Magellan. One of the largest and most difficult engineering projects ever undertaken, the Panama Canal shortcut made it possible for ships to travel between the Atlantic and Pacific Oceans in half the time previously required. The shorter, faster, safer route to the US West Coast and to nations in and along the Pacific Ocean allowed those places to become more integrated with the world economy.

During this time, ownership of the territory that is now the Panama Canal was first Colombian, then French, and then American; the United States completed the construction. The canal was taken over in 1999 by the Panamanian government, as long planned. Annual traffic has risen from about 1,000 ships when the canal opened in 1914, to 14,702 vessels in 2008, the latter measuring a total of 309.6 million Panama Canal/Universal Measurement System (PC/UMS) tons. By 2008, more than 815,000 vessels had passed through the canal, many of them much larger than the original planners could have envisioned; the largest ships that can transit the canal today are called Panamax. The American Society of Civil Engineers has named the Panama Canal one of the seven wonders of the modern world.

History

The earliest mention of a canal across the Isthmus of Panama dates to 1534, when Charles V, Holy Roman Emperor and King of Spain, ordered a survey for a route through the Americas that would ease the voyage for ships traveling between Spain and Peru. Such a route would have given the Spanish a military advantage over the Portuguese. During an expedition from 1788 to 1793, Alessandro Malaspina outlined plans for its construction.

Given the strategic location of Panama and the potential offered by its narrow isthmus separating two great oceans, other trade links in the area were attempted over the years. An ill-fated Darien scheme was launched by the Kingdom of Scotland in 1698 to set up an overland trade route. Generally inhospitable conditions thwarted the effort, and it was abandoned in July 1699.

In 1849, the discovery of gold in California created great interest in a crossing between the Atlantic and Pacific Oceans. Eventually, the Panama Railway was built to cross the isthmus, opening in 1855. This overland link became a vital piece of Western Hemisphere infrastructure, greatly facilitating trade and largely determining the later canal route.

An all-water route between the oceans was still seen as the ideal solution, and in 1855 William Kennish, a Manx-born engineer working for the United States government, surveyed the isthmus and issued a report on a route for a proposed Panama Canal. His report was published in a book entitled The Practicality and Importance of a Ship Canal to Connect the Atlantic and Pacific Oceans.

In 1877 Armand Reclus, an officer with the French Navy, and Lucien Napoléon Bonaparte Wyse, two engineers, surveyed the route and published a French proposal for a canal. French success in building the Suez Canal, while a lengthy project, encouraged planning for one to cross the isthmus.

French construction, 1881–89

In 1881, the first attempt to construct a sea-level canal began under the leadership of Ferdinand de Lesseps, builder of the Suez Canal, with substantial financing and support from Paris. The French effort went bankrupt after losing an estimated 22,000 lives and reportedly spending US $287,000,000, and was largely abandoned by 1890. The Suez Canal was built in a much more benign environment but still took 10 years to complete its 164 kilometres (102 mi) length, about twice that of the Panama Canal. Under de Lesseps' control, construction began on a sea-level (i.e., without locks) canal through what was then Colombia's province of Panama, on January 1, 1881. The French rushed to begin work, with insufficient prior study of the geology and hydrology of the region. Excavation was conducted at such a steep angle that, in some years, rain-induced landslides poured nearly as much material into the canal as had been removed.

The cost and difficulty of building a canal in the rain-soaked tropics through unstable mountains exceeded expectations. Health risks posed to workers in the mosquito-infested Panamanian jungle, principally malaria and yellow fever, cost thousands of lives and caused unanticipated delays. Public health measures were ineffective because the role of the mosquito as a disease vector was then unknown. Accidents and disease cost the lives of about 22,000 workers. The high mortality made it very difficult to maintain an experienced workforce. Those French-trained technical employees and engineers who remained healthy often quickly returned to France after discovering the true work conditions. Even the hospitals contributed to the problem, with conditions that unintentionally provided breeding places for mosquitoes inside the unscreened wards.

Added to this, the men who started and directed the project had little or no engineering training or experience, which contributed to a gross underestimation of the difficulty they would encounter, as building the Panama Canal was a project of great scale. The geology defeated them, as canals cut through mountains had to continually be widened, and their slopes reduced, to minimize landslides into the canal. Lack of field experience in this environment, and the problems such as tropical downpours that caused steel equipment to rust rapidly, contributed to the difficulties. In addition, limited types of heavy-duty engineering and electrical equipment were available in this period. Steam shovels had been invented but were still primitive, as were other types of heavy-duty equipment; electrical generators, electrical motors, electrical distribution systems, and the like were still in their infancy. Nikola Tesla had just invented the alternating current (AC) motor in 1886. Beyond the health and technical difficulties, financial mismanagement and political corruption also contributed to the French failure.

Conditions were downplayed in France to avoid recruitment problems; but in 1893, after a great deal of work, the French scheme was abandoned. Disease and the sheer difficulty of building a sea-level canal were ultimately insurmountable.

In 1894, a second French company, the Compagnie Nouvelle du Canal de Panama, was created to finish the construction. A minimal workforce of a few thousand people was employed primarily to comply with the terms of the Colombian Panama Canal concession, to run the Panama Railroad, and to maintain the existing excavation and equipment in salable condition. The company sought a buyer for these assets, with an asking price of US$109,000,000.

1890–1903

At this time, various parties in the United States were interested in establishing a canal across the isthmus, with some favoring a route across Nicaragua (see Nicaragua Canal and Ecocanal) and others advocating the purchase of the French interests in Panama. A U.S. engineering panel was commissioned to study the potential of building the canal and recommended a sea-level canal to President Theodore Roosevelt. However, more extensive engineering studies favored a canal using a lock system to raise and lower ships from a large reservoir 85 ft (26 m) above sea level. This canal design was recommended to Roosevelt by Chief Engineer John Frank Stevens and was agreed to by him. The 115 ft (35 m)-high Gatun Dam would create both the largest dam and the largest man-made lake ( Gatun Lake) in the world at that time. In the end, a canal that operated with an elevated reservoir and a system of three locks to raise ships above sea level to Gatun Lake, and then lower them on the opposite ocean with another set of three locks, was seen as much less expensive, faster to build, and more feasible in design than the original vision of a sea-level canal. The water to fill and empty the locks would be taken from Gatun Lake by opening and closing enormous gates and valves and letting gravity propel the water from the lake. Gatun Lake would connect to the Pacific through the mountains at the Gaillard (Culebra) Cut.

"Brig. Gen. Henry Larcom Abbot, coauthor of a classic work on the hydrology of the Mississippi River, began his involvement with the Panama Canal as a member of the new French canal company’s Comité Technique and Comité Statutaire, from 1897 to 1900. While the United States was assuming responsibility for building the Canal, Abbot worked for the French company as a consulting engineer during the transitional period, dividing his time between Paris and the isthmus. After the Americans assumed control of the project Abbot served from 1905 to 1906 on the Board of Consulting Engineers, a body appointed by Roosevelt and charged with the preparation of a plan for canal construction. The majority of the board recommended a sea-level canal. The minority report, probably written largely by Abbot, helped to persuade Roosevelt and Secretary of War William Howard Taft to adopt a plan for a lock canal. Abbot’s last service to the canal was as a member of the Panama Canal Slide Committee in 1915."

Eventually, in June 1902, the U.S. Senate voted in favour of pursuing the Panamanian option, provided the necessary rights could be obtained. (It is claimed that the vote was swayed by William Nelson Cromwell.)

On January 22, 1903, the Hay-Herran Treaty was signed by United States Secretary of State John M. Hay and Dr. Tomás Herrán of Colombia. It would have granted the United States a renewable lease in perpetuity from Colombia on the land proposed for the canal. This is often misinterpreted as the "99-year lease" because of misleading wording included in article 22 of the agreement. That wording refers to property within the purchased area, but does not pertain to control of the canal or the right of the United States to renew its lease indefinitely. The treaty was ratified by the U.S. Senate on March 14, 1903, but the Senate of Colombia did not ratify it. Phillipe Bunau-Varilla, chief engineer and significant shareholder of the French canal company, told U.S. President Theodore Roosevelt and Hay of a possible revolt, and hoped that the United States would support Panamanian rebels who aimed to separate from Colombia by providing U.S. troops and money. Roosevelt changed tactics, promising support for the separation of Panama from Colombia.

On November 2, 1903, U.S. warships blocked sea lanes for possible Colombian troop movements en route to put down the rebellion. Dense jungles blocked Colombia's land routes. Reportedly, extensive bribes were paid to get the few Colombian troops stationed in Panama to lay down their arms. Panama declared independence the next day, November 3, 1903. The United States quickly recognized the new nation. On November 6, 1903, Phillipe Bunau-Varilla, Panama's ambassador to the United States, signed the Hay–Bunau-Varilla Treaty, granting rights to the United States to build and indefinitely administer the Panama Canal Zone and its defenses. Although Bunau-Varilla was serving as Panama's ambassador, he was a French citizen and not officially authorized to sign treaties on behalf of Panama without Panamanian review. This would later become a contentious diplomatic issue between Panama and the United States.

United States acquisition, 1904

In 1904, the United States, under President Theodore Roosevelt, bought the French equipment and excavations for US $40 million, paid the new country of Panama US $10 million plus more each year, and began work on the Panama Canal on May 4. (In 1921, the United States paid Colombia US $10 million, plus US $250,000 per annum for several years; in return, Colombia recognized Panama under the terms of the Thomson-Urrutia Treaty).

The U.S. purchase of the French concession for US $40 million included the Panama Railroad. Further, it was estimated that French excavation of about 30,000,000 cu yd (23,000,000 m3), primarily in the Gaillard Cut (then called the Culebra Cut), was of direct use to the U.S. construction effort and was valued at about $1.00 per 1 cu yd (1 m3), or $30,000,000. The remaining usable French equipment, engineering surveys, etc., were valued at about $10,000,000 more.

Isthmian Canal Commission

The Isthmian Canal Commission (ICC) was a U.S. government commission set up to oversee the construction of the Panama Canal in the early years of American involvement. Established in 1904, it was given control of the Panama Canal Zone, over which the United States exercised sovereignty. The commission reported directly to Secretary of War William Howard Taft.

It was initially composed of seven members, appointed by President Theodore Roosevelt, directed to avoid the inefficiency and corruption that had plagued the French 15 years earlier. On May 6, 1904, President Theodore Roosevelt appointed John Findlay Wallace, formerly chief engineer and finally general manager of the Illinois Central Railroad, chief engineer of the Panama Canal project. Wallace was paid a $25,000 annual salary, the highest of any government employee at that time other than the president. In addition to the engineering and health problems, Wallace faced many bureaucratic challenges from the ICC, which had to approve essentially every significant decision Wallace made in the Canal Zone. With engineers filling out more than 1,000 work request forms weekly, even the simplest tasks often took months to complete. In addition to "make dirt fly", as directed by Roosevelt, Wallace was forced to use the often dilapidated infrastructure and equipment left behind by the French when they sold their concession.

The ICC was later reduced to three members on the recommendation of John Findlay Wallace, the chief engineer. Overwhelmed, Wallace resigned abruptly in June 1905. In 1906 when a new chief engineer, John Frank Stevens, was appointed, he was not a member of the commission. He increasingly viewed the bureaucratic ICC as a serious hindrance and ended up bypassing the commission and sending requests and demands directly to the Roosevelt Administration in Washington.

In Washington, D.C., Joseph Bucklin Bishop, an associate of Theodore Roosevelt and a strong editorial advocate for U.S. participation in the canal project, was appointed Executive Secretary of the Isthmian Canal Commission the following year (1905). Bishop was tasked with managing the commission's day-to-day matters, but also with ensuring public support for the canal through public relations and by keeping the project's official history. Bishop's promised $10,000 annual salary was relentlessly criticized by Roosevelt's opponents in Congress, mostly because it was twice what each of them made. Opposition newspapers joined in the criticism. In the summer of 1907, when escalating allegations of cronyism surrounding Bishop's appointment threatened appropriations for Panama Canal construction, Taft, surely with Roosevelt's quiet assent, ordered Bishop out of Washington to Panama, where the partisan political heat would be less intense. "I accept your decision without reluctance", Bishop informed Taft, "and shall go to the Isthmus, not sadly but cheerfully." It would not be his first trip to Panama. In the fall of the previous year, Bishop had gone ahead to advance Roosevelt's historic inspection tour, the first time a sitting president had journeyed outside the United States.

Joseph Bucklin Bishop would, except for month-long summer breaks, remain on the isthmus for seven years, serving clandestinely at first as Theodore Roosevelt's "eyes and ears". He reported back on the "astonishing" progress that Army Corps of Engineers Colonel George Washington Goethals and his team were making excavating the "big ditch", building dams and locks. Before long, Bishop became Goethals's trusted aide, serving as his first line of defense against workers with complaints and grievances. But Bishop's greatest achievement in Panama would be as founding editor of The Canal Record, a weekly newspaper for the thousands of workers in Panama. His regular reports of the cubic yards dug by rival work divisions, and the competitive baseball games they played, created a spirit of healthy competition that lifted worker morale and productivity. The "good news" of The Canal Record also built vital public support on newspaper editorial pages back home and in the halls of the United States Congress, where annual appropriations were required to keep the canal project moving forward.

U.S. Panama Canal construction, 1904–14

(For Panama Canal Pictures see:)

On May 6, 1904, President Theodore Roosevelt appointed John Findlay Wallace, formerly chief engineer and finally general manager of the Illinois Central Railroad, chief engineer of the Panama Canal Project. Overwhelmed by the disease-plagued country and forced to used often dilapidated French infrastructure and equipment as well as being frustrated by the overly bureaucratic ICC, Wallace resigned abruptly in June 1905.

John Frank Stevens, a self-educated engineer who had built the Great Northern Railroad, and chief engineer of the Panama Canal from 1905 to 1907, successfully argued the case against the sea-level canal, such as the French had attempted. He convinced Roosevelt of the necessity and feasibility of a canal built with large dam and lake system with three double sets of locks to raise ships to the level of the reservoir and then lower them in locks at the other ocean.

One of Stevens' primary achievements in Panama was in building and rebuilding the housing, cafeterias, hotels, water systems, repair shops, warehouses, and other infrastructure needed by the thousands of incoming workers. Stevens tried to provide accommodations where the incoming workers could work and reside in reasonable safety and comfort. He began the recruitment effort to entice thousands of workers from the United States and other areas to come to the Canal Zone to work. Initially, the reputation of the Canal Zone made recruiting labor difficult. The major inducements were wages ranging from $0.90 per day for common laborers to $8.00 per day for steam shovel operators, a nine-hour work day, three meals a day for as low as $0.30 per day, subsidized housing, vacation and sick leave, along with full medical coverage for nearly all. After a few years, when it became clear that the Canal Zone was a reasonably safe place (for the time) to work with good wages and hours, labor recruitment became much easier.

Stevens saw to the Panama Railway's rebuilding and upgrading with modern heavy-duty equipment. The railroad, starting in 1904, had to be comprehensively upgraded with heavy-duty, double-tracked rails over most of the line to accommodate new rolling stock of about 115 heavy-duty locomotives and 2,300 dirt spoils railroad cars. The new Panama Railroad closely paralleled the canal where feasible, but was moved and reconstructed where it interfered with canal work. In many places, the new Gatun Lake flooded over the original rail line, and a new line had to be constructed above Gatun Lake's waterline by raising the track with massive dirt fills (using excavated materials from the Gaillard Cut and elsewhere) or by building bridges.

Building the Gatun Lake reservoir would require less excavation by expensive steam shovels and allow more excavation work that could be done with less expensive dredges. The dredges could excavate material at a cost of about $0.25–0.50 per cubic yard, roughly half the cost of the shovels. The construction of a Panama Canal with locks still required the excavation of more than an additional 170,000,000 cu yd (130,000,000 m3) of material over and above the 30,000,000 cu yd (23,000,000 m3) excavated by the French. The lock canal and Gatun Lake reduced by roughly half the amount of excavation needed for an elevated canal vis-à-vis a sea-level canal, and saved several hundreds of millions of dollars and years of time. Where necessary, in Gatun Lake, a ship channel could be reasonably cheaply dredged deeper.

Colonel William C. Gorgas, formerly chief sanitation officer in Havana, Cuba, under Dr. Walter Reed, was appointed chief sanitation officer of the canal construction project in 1904. Dr. Carlos Finlay had postulated in 1881 that mosquitoes may be key to transmitting yellow fever and malaria. After the 1898 Spanish-American War, Finlay's theory was confirmed by Dr. Walter Reed of the U.S. Army Medical Corps while in Havana in 1900. (See also: Health measures during the construction of the Panama Canal.) Implementing the recommendations of Reed and Dr. William Gorgas, Stevens also built proper housing with screens for canal workers and oversaw investment in extensive sanitation projects, including extensive city water systems and mosquito-abatement programs to minimize the spread of deadly mosquito-spread diseases, particularly malaria and yellow fever.

The sanitation and mosquito abatement projects involved identifying and isolating patients with yellow fever or malaria; fumigation of buildings by burning sulfur or pyrethrum to kill mosquitoes; spraying insect-breeding areas with oil and larvicide; paving roads in Panamanian towns to minimize stagnant water; installing mosquito netting over beds; introduction of window screens; installing citywide water systems to minimize or eliminate the often stagnant drinking water stored in cisterns; elimination of stagnant water in open containers; and draining swamps; among other measures. Even with all this effort, about 5,600 workers died of disease and accidents during the U.S. construction phase of the canal.

After two years of extensive sanitation and mosquito abatement work involving thousands of workers and millions of dollars, the mosquito-spread diseases were nearly eliminated. Extensive work, also involving thousands and costing millions, was done on preparing the infrastructure needed by the workers and their equipment. After the upgrading of the Panama Railroad and other preliminary work were completed, the construction of an elevated canal with locks began in earnest.

Chief Engineer John Frank Stevens envisioned this work as essentially a massive earth-moving project that required using a new and expanded Panama Railway as efficiently as possible. Stevens' previous work as chief engineer of the Northern Pacific Railroad, where several 1,000 mi (1,600 km) of track had been built, had prepared him well for this task. Much of the excavated material was used to build part of the Gatun Dam and the new elevated railroad across Gatun Lake. In addition to hauling the thousands of workers and millions of tons of supplies, equipment, and spoils from the canal construction, the railroad had to continue to carry its usual extensive loads of commercial freight and passengers to and from the Atlantic and Pacific Oceans. Stevens resigned in 1907 as the work changed to primarily canal and lock construction.

"American work on the canal began in 1904. The first two chief engineers of the project were railroad men, John F. Wallace and John F. Stevens. Both soon quit their positions. In 1907 President Theodore Roosevelt announced that he would appoint a chief engineer that could not resign. He chose U.S. Army Major George Washington Goethals of the U.S. Army Corps of Engineers (soon to be promoted to lieutenant colonel and later to colonel), a strong, United States Military Academy–trained leader and civil engineer. Like many other Army engineers, Goethals had much experience in the designing and building of canals, locks, and dams. He directed the work in Panama to a successful conclusion in 1914."

In 1907, President Roosevelt appointed Colonel Goethals to succeed Stevens as chief engineer on the Panama Canal construction project. Chief engineer from 1907 to 1914, he divided the engineering and excavation work into three divisions: Atlantic, Central, and Pacific. The Atlantic division, under Major William L. Sibert, was responsible for construction of the massive breakwater at the entrance to Limon Bay, the Gatun locks and their 3.5 mi (5.6 km) approach channel, and the immense Gatun Dam. The Pacific Division, under Sydney B. Williamson (the only civilian member of this high-level team), was similarly responsible for the Pacific 3.0 mi (4.8 km) breakwater in Panama Bay, the approach channel to the locks, and the Miraflores and Pedro Miguel locks and their associated dams and reservoirs.

The Central division, under Major David du Bose Gaillard of the United States Army Corps of Engineers, was assigned one of the most difficult parts: excavating the Gaillard Cut (then called the Culebra Cut) through the continental divide to connect Gatun Lake to the Pacific Panama Canal locks. Building a usable ship channel through the Galliard Cut involved excavating a wide "V"-shaped trench through the often unstable mountains to get a stable 300 ft (91 m) wide ship channel. The Pacific end of the Gaillard Cut is about 8 mi (13 km) from the Pedro Miguel lock. The water in the cut has about a 300 ft (91 m) wide ship channel, a water level of about 85 ft (26 m), and a bottom of channel depth of about 40 ft (12 m) above sea level. Building Gatun Dam and Gatun Lake together with six double sets of ship locks reduced the amount of earth that needed to be excavated in the Galliard Cut by about 85 ft (26 m) in depth by about 13 mi (21 km) long, with a variable "V"-shaped cut of 300 ft (91 m) to 2,600 ft (790 m) in width, roughly halving the amount of material that would have had to be removed using an elevated canal design. In addition, the dam and lake provided a way to tame the often wild seasonal fluctuation of water levels in the Chagres River, the main source of water to Gatun Lake. The height of Gatun Lake is kept fairly constant by allowing excess water to go over the spillway near the Gatun Locks in the rainy season; the lake water effluent that does not pass through the locks or over the spillway generates hydroelectric power year-round.

About 102 new large, railroad-mounted steam shovels were purchased and brought in from the United States. These shovels were some of the largest in the world when they were introduced in 1906, and were used primarily on the Gaillard Cut and the lock-building projects. The excavated material was broken up by explosives, and then the loosened dirt was scooped up by shovels mounted on one set of railroad tracks, which loaded the loose earth onto spoils railroad cars mounted on parallel tracks. (See: Marion Steam shovel in action mounted on caterpillar tracks—YouTube) The spoils cars were then hauled out by locomotives to a dump site or other site in need of back fill material. The Gatun Dam and Panama Railroad were two of the big users of this material. The interplay of getting dirt cars in place to load as quickly as possible and the limitations on the available dirt cars, tracks, locomotives, and the like meant that the average steam shovel only worked about 50% of each nine-hour day. Some of this downtime was used for maintenance, repairs, and re-coaling the shovels. The Bucyrus company made 70 of the 102 steam shovels used; the Marion Power Shovel Company built the remaining 32. Marion was acquired by Bucyrus in 1997, and the combined company was acquired by Caterpillar Inc. in a deal costing US$8.8 billion completed on July 8, 2011.

Most of the cars carrying the dirt spoils were wooden flat cars lined with steel floors that used a crude but effective unloading device, the Lidgerwood system. The railroad cars had only one closed side, and steel aprons bridged the spaces between the cars. The dirt was piled high up against the closed side of the car. The train moved forward as the cars were filled until all its cars were filled. A typical train had twenty such dirt cars arranged as one long gondola car. Upon the arrival of the train at one of the approximately 60 different dumping grounds, a three-ton steel plow was put on the last car (or a car carrying the plow was attached as the last car) and a large winch with a braided steel cable stretching the length of all cars was attached to the engine. The winch, powered by the train's steam engine, pulled the plow the length of the dirt-loaded train by winching up the steel cable. The plow scraped the dirt off the railroad cars, allowing the entire trainload of dirt cars to be unloaded in about ten minutes or less. The plow and winch were then detached for use on another spoils train. Another plow, mounted on the side of a steam engine, then plowed the dirt spoils away from the track. When the fill got large enough, the track was relocated on top of the old fill to allow almost continuous unloading of new fill with a minimum amount of effort.

William Bierd, former head of the Panama Railroad, developed techniques to pick up large sections of track and their attached ties, intact, when the steam shovels or dirt trains needed to move to a new section. A dozen men using steam-powered cranes could relocate a mile of track a day this way, because there was no need to disassemble and rebuild each section of track—work that previously had taken up to 600 men. This allowed the tracks used by both the steam shovels and the dirt trains to be quickly moved to wherever they needed to go. While constructing the Gaillard Cut, about 160 loaded dirt trains went out of the cut daily and returned empty, at a rate of one train about every one and a half minutes.

The railroads, steam shovels, enormous steam-powered cranes, giant hydraulic rock crushers, cement mixers, dredges, and pneumatic power drills used to drill holes for explosives (about 30,000,000 lb (14,000,000 kg) were used) were some of the new (in 1906) pieces of construction equipment used to construct the canal. Nearly all this equipment was manufactured by new, extensive machine-building technology developed and built in the United States. The giant hydraulic rock crushers supplied by the Joshua Hendy Iron Works were used to grind up rock needed for the cement work and quicken the pace of construction; large Ellicott Dredges of Baltimore, Maryland sped up some of the various dredging projects. The first piece that Ellicott Dredge delivered was a steam-driven, 900 hp (670 kW), 20-inch suction dredge used to help dig canal channels and fill Gatun Dam with dredged-up slurry. In 1941, Ellicott Dredges also built the dredge MINDI, a 10,000 hp (7,500 kW), 28-inch cutter suction dredge still operating in the Panama Canal. Arch rivals General Electric and Westinghouse provided many of the electrical controls, motors, and generators. The Panama Canal project had one of the largest and most extensive electrical installations in the world early in the 1900s. It uses over 1000 electric motors with an installed capacity of about 28,000 horsepower to control its locks and valves from a central location.

In addition, the canal used large refrigeration systems for making ice. The Panama Canal locks used essentially no pumps but relied on giant electrical valves and gates to control the flow of water from Gatun Lake into and out of the locks through water tunnels the size of railroad tunnels.

As quickly as possible, the Americans replaced or upgraded the old, unusable French equipment with new construction equipment that was designed for a much larger and faster scale of work to quicken the pace of construction, earth cuts, and fills. The technology succeeded in excavating many times the material that was moved with the original 1851–55 railroad construction—done essentially by hand and black powder explosives. Unusable French equipment was dug out of the jungle and sold as scrap. President Roosevelt had some of the brass in the old French machinery minted into medals for all workers who spent at least two years on the construction, to commemorate their contribution to the building of the canal. These medals featured Roosevelt's likeness on the front, the name of the recipient on one side, and the worker's years of service, as well as a picture of the Culebra Cut, on the back.

The building of the canal was completed in 1914, 401 years after Panama was first crossed by Vasco Núñez de Balboa. One of several new innovations was the four to eight electrical-powered "mule engines" on each side of the locks that were attached to each ship to stabilize their passage through the locks as they were guided through by canal pilots.

In the end, the engineers and workers minimized the mosquito threat; moved, rebuilt, and expanded the Panama Railroad; excavated over 200,000,000 cu yd (150,000,000 m3) of earth; built the world's largest (then) dam and a lake; poured about 2,000,000 cu yd (1,500,000 m3) of concrete creating a spillway at Gatun Lake to control its height; and formed three sets of double 110 feet (34 m) by 1,000 ft (300 m) ship's locks, then the largest concrete pour in the world. This was supported by an extensive buildup of U.S.-built, then-modern, heavy-duty excavation and construction equipment, and one of the world's earliest and most extensive electrical systems, used to power and control the flow of water into the locks and spillway. The United States spent almost $375,000,000 (roughly equivalent to $8,600,000,000 now), including $12,000,000 to build facilities used to guard the canal, to finish the project. This was by far the largest American engineering project of that or any previous era. The canal was formally opened on August 15, 1914, with the passage of the cargo ship SS Ancon. Coincidentally, this was also the same month that fighting in World War I began in Europe. The advances in hygiene resulted in a relatively low death toll during the American construction; still, about 5,600 workers died during this period (1904–14), bringing the total death toll for the construction of the canal to around 27,500.

The American Society of Civil Engineers has named the Panama Canal one of the seven wonders of the modern world.

Later developments

By the 1930s it was seen that water supply would be an issue for the canal; this prompted the building of the Madden Dam across the Chagres River above Gatun Lake. The dam, completed in 1935, created Madden Lake (later Alajuela Lake), which provides additional water storage for the canal. In 1939, construction began on a further major improvement: a new set of locks for the canal, large enough to carry the larger warships that the United States was building at the time and had planned to continue building. The work proceeded for several years, and significant excavation was carried out on the new approach channels, but the project was canceled after World War II.

|

Statement on the Panama Canal Treaty Signing

Jimmy Carter's speech upon signing the Panama Canal treaty, 7 September 1977.

|

| Problems listening to this file? See media help. | |

After World War II, U.S. control of the canal and the Canal Zone surrounding it became contentious; relations between Panama and the United States became increasingly tense. Many Panamanians felt that the Canal Zone rightfully belonged to Panama; student protests were met by the fencing-in of the zone and an increased military presence there. Demands for the United States to hand over the canal to Panama increased after the Suez Crisis in 1956, when the US used financial and diplomatic pressure to force France and the UK to abandon their attempt to retake control of the Suez Canal, previously nationalized by the Nasser regime in Egypt. Unrest culminated in riots on Martyr's Day, January 9, 1964, when approximately 20 Panamanians and 3–5 U.S. soldiers were killed. A decade later, in 1974, negotiations toward a settlement began and resulted in the Torrijos-Carter Treaties. On September 7, 1977, the treaty was signed by President of the United States Jimmy Carter and Omar Torrijos, de facto leader of Panama. This mobilized the process of granting the Panamanians free control of the canal so long as Panama signed a treaty guaranteeing the permanent neutrality of the canal. The treaty led to full Panamanian control effective at noon on December 31, 1999, and the Panama Canal Authority (ACP) assumed command of the waterway. The Panama Canal remains one of the chief revenue sources for Panama.

Before this handover, the government of Panama held an international bid to negotiate a 25-year contract for operation of the container shipping ports located at the canal's Atlantic and Pacific outlets. The contract was not affiliated with the ACP or Panama Canal operations and was won by the firm Hutchison Whampoa, a Hong Kong–based shipping interest owned by Li Ka-shing.

Canal

Layout

| Panama Canal map | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

While, globally, the Atlantic Ocean is east of the isthmus and the Pacific to the west, the general direction of the canal passage from the Atlantic to the Pacific is from northwest to southeast. This is because of a local anomaly in the shape of the isthmus at the point the canal occupies. The Bridge of the Americas (Spanish: Puente de las Américas) at the Pacific side is about a third of a degree east of the Colón end on the Atlantic side. Still, in formal nautical communications, the simplified directions "Southbound" and "Northbound" are used.

The canal consists of artificial lakes, several improved and artificial channels, and three sets of locks. An additional artificial lake, Alajuela Lake (known during the American era as Madden Lake), acts as a reservoir for the canal. The layout of the canal as seen by a ship passing from the Atlantic to the Pacific is as follows:

- From the formal marking line of the Atlantic Entrance, one enters Limón Bay (Bahía Limón), a large natural harbour. The entrance runs 5.4 mi (8.7 km). It provides a deepwater port ( Christóbal), with facilities like multimodal cargo exchange (to and from train) and the Colón Free Trade Zone (a free port).

- A 2.0 mi (3.2 km) channel forms the approach to the locks from the Atlantic side.

- The Gatun locks, a three-stage flight of locks 1.2 mi (1.9 km) long, lifts ships to the Gatun Lake level, some 87 ft (26.5 m) above sea level.

- Gatun Lake, an artificial lake formed by the building of the Gatun Dam, carries vessels 15 mi (24.2 km) across the isthmus. It is the summit canal stretch, fed by the Gatun river and emptied by basic lock operations.

- From the lake, the Chagres River, a natural waterway enhanced by the damming of Gatun Lake, runs about 5.3 mi (8.5 km). Here the upper Chagres river feeds the high level canal stretch.

- The Culebra cut slices 7.8 mi (12.6 km) through the mountain ridge, crosses the continental divide and passes under the Centennial Bridge.

- The single-stage Pedro Miguel lock, which is 0.87 mi (1.4 km) long, is the first part of the descent with a lift of 9.5 meters (31 ft).

- The artificial Miraflores Lake, 1.1 mi (1.7 km) long, and 16.5 meters (54 ft) above sea level.

- The two-stage Miraflores locks, is 1.1 mi (1.7 km) long, with a total descent of 54 ft (16.5 m) at mid-tide.

- From the Miraflores locks one reaches Balboa harbour, again with multimodal exchange provision (here the railway meets the shipping route again). Nearby is Panama City.

- From this harbour an entrance/exit channel leads to the Pacific Ocean ( Gulf of Panama), 8.2 mi (13.2 km) from the Miraflores locks, passing under the Bridge of the Americas.

Thus, the total length of the canal is 48 mi (77.1 km).

| Point | Coordinates (links to map & photo sources) |

Notes |

|---|---|---|

| Atlantic Entrance | 9.38743°N 79.91863°W | |

| Gatún Locks | 9.27215°N 79.92266°W | |

| Trinidad Turn | 9.20996°N 79.92408°W | |

| Bohío Turn | 9.17831°N 79.86667°W | |

| Orchid Turn | 9.18406°N 79.84513°W | |

| Frijoles Turn | 9.15904°N 79.81362°W | |

| Barbacoa Turn | 9.12053°N 79.80395°W | |

| Mamei Turn | 9.11161°N 79.76856°W | |

| Gamboa Reach | 9.11774°N 79.72257°W | |

| Bas Obispo Reach | 9.09621°N 79.68446°W | |

| Las Cascadas Reach | 9.07675°N 79.67492°W | |

| Empire Reach | 9.06104°N 79.66309°W | |

| Culebra Reach | 9.04745°N 79.65017°W | |

| Cucaracha Reach | 9.03371°N 79.63736°W | |

| Paraiso Reach | 9.02573°N 79.62492°W | |

| Pedro Miguel Locks | 9.01698°N 79.61281°W | |

| Miraflores Lake | 9.00741°N 79.60254°W | |

| Miraflores Locks | 8.99679°N 79.59182°W | |

| Balboa Reach | 8.97281°N 79.57771°W | |

| Pacific Entrance | 8.88846°N 79.52145°W |

Gatun Lake

Created in 1913 by the damming of the Chagres River, Gatun Lake is an essential part of the Panama Canal which forms a water passage between the Atlantic and Pacific Oceans, permitting ship transit in both directions. At the time it was formed, Gatun Lake was the largest man-made lake in the world. The impassable rainforest around the lake has been the best defense of the Panama Canal. Today these areas remain practically unscathed by human interference and are one of the few accessible areas on earth where various native Central American animal and plant species can be observed undisturbed in their natural habitat. World famous Barro Colorado Island, which was established for scientific study when the lake was formed and is today operated by the Smithsonian Institution, is the largest island on Gatun Lake. Many of the most important groundbreaking scientific and biological discoveries of the tropical animal and plant kingdom originated here. Gatun Lake covers approximately 180 square miles (470 km2), a vast tropical ecological zone part of the Atlantic Forest Corridor. Ecotourism on the lake has become a worthwhile industry for Panamanians.

Gatun Lake also serves to provide the millions of gallons of water necessary to operate the Panama Canal locks each time a ship passes through, and provides drinking water for Panama City and Colón. Fishing is one of the primary recreational pursuits on Gatun Lake. Non-native Peacock Bass were introduced by accident to Gatun Lake around 1967 by a local businessman, and have since flourished to become the dominant angling game fish in Gatun Lake. Locally called Sargento and believed to be the species Cichla pleiozona, these peacock bass are not a native game fish of Panama but originate from the Amazon, Rio Negro, and Orinoco river basins of South America, where they are called Tucanare or Pavon and considered a premier game fish.

Lock size

The size of the locks determines the maximum size of a ship that can pass through them. Because of the importance of the canal to international trade, many ships are built to the maximum size allowed. These are known as Panamax vessels. A Panamax cargo ship typically has a DWT of 65,000–80,000 tonnes, but its actual cargo is restricted to about 52,500 tonnes because of the 41.2 feet (12.6 m) draft restrictions within the canal. The longest ship ever to transit the canal was the San Juan Prospector (now Marcona Prospector), an ore-bulk-oil carrier that is 973 ft (296.57 m) long with a beam of 106 ft (32.31 m).

Initially the locks at Gatun had been designed to be 28.5 meters (94 ft) wide. In 1908, the United States Navy requested that width be increased to at least 36 meters (118 ft), which would allow the passage of U.S. naval ships. Eventually a compromise was made and the locks were built 33.53 meters (110.0 ft) wide. Each lock is 320 meters (1,050 ft) long, with the walls ranging in thickness from 15 meters (49 ft) at the base to 3 meters (9.8 ft) at the top. The central wall between the parallel locks at Gatun is 18 meters (59 ft) thick and over 24 meters (79 ft) high. The steel lock gates measure an average of 2 meters (6.6 ft) thick, 19.5 meters (64 ft) wide, and 20 meters (66 ft) high. It is the size of the locks, specifically the Pedro Miguel Locks, along with the height of the Bridge of the Americas at Balboa, that determine the Panamax metric and limit the size of ships that may use the canal.

The 2006 third set of locks project will create larger locks, allowing bigger ships to transit through deeper and wider channels. The allowed dimensions of ships will increase by 25% in length, 51% in beam, and 26% in draft, as defined by New Panamax metrics.

Tolls

Tolls for the canal are set by the Panama Canal Authority and are based on vessel type, size, and the type of cargo carried.

For container ships, the toll is assessed on the ship's capacity expressed in twenty-foot equivalent units, or TEUs. One TEU is the size of a container measuring 20 feet (6.1 m) by 8 feet (2.44 m) by 8.5 feet (2.6 m). Effective May 1, 2009, this toll is US$72.00 per TEU. A Panamax container ship may carry up to 4,400 TEU. The toll is calculated differently for passenger ships and for container ships carrying no cargo ("in ballast"). As of May 1, 2009, the ballast rate is US$57.60 per TEU.

Passenger vessels in excess of 30,000 tons (PC/UMS), known popularly as cruise ships, pay a rate based on the number of berths, that is, the number of passengers that can be accommodated in permanent beds. The per-berth charge is currently $92 for unoccupied berths and $115 for occupied berths. Started in 2007, this fee has greatly increased the tolls for such ships. Passenger vessels of less than 30,000 tons or less than 33 tons per passenger are charged according to the same per-ton schedule as are freighters.

Most other types of vessel pay a toll per PC/UMS net ton, in which one "ton" is actually a volume of 100 cubic feet (2.83 m3). (The calculation of tonnage for commercial vessels is quite complex.) As of fiscal year 2008, this toll is US$3.90 per ton for the first 10,000 tons, US$3.19 per ton for the next 10,000 tons, US$3.82 per ton for the next 10,000 tons, and US$3.76 per ton thereafter. As with container ships, a reduced toll is charged for freight ships "in ballast".

Small vessels up to 583 PC/UMS net tons when carrying passengers or cargo, or up to 735 PC/UMS net tons when in ballast, or up to 1,048 fully loaded displacement tons, are assessed minimum tolls based upon their length overall, according to the following table:

| Length of vessel | Toll |

|---|---|

| Up to 15.240 meters (50 ft) | US$1,300 |

| More than 15.240 meters (50 ft) up to 24.384 meters (80 ft) | US$1,400 |

| More than 24.384 meters (80 ft) up to 30.480 meters (100 ft) | US$1,500 |

| More than 30.480 meters (100 ft) | US$2,400 |

The most expensive regular toll for canal passage to date was charged on April 14, 2010 to the cruise ship Norwegian Pearl, which paid US$375,600. The average toll is around US$54,000. The highest fee for priority passage charged through the Transit Slot Auction System was US$220,300, paid on August 24, 2006, by the Panamax tanker Erikoussa, bypassing a 90-ship queue waiting for the end of maintenance works on the Gatun locks, thus avoiding a seven-day delay. The normal fee would have been just US$13,430.

Current issues

In the 99 years since its opening, the canal continues to enjoy great success. Even though world shipping—and the size of ships themselves—has changed markedly since the canal was designed, it continues to be a vital link in world trade, carrying more cargo than ever before, with fewer overhead costs. Nevertheless, the canal faces a number of potential concerns.

Efficiency and maintenance

Opponents to the 1977 Torrijos-Carter Treaties feared that efficiency and maintenance would suffer following the U.S. withdrawal from the Panama Canal Zone; however, this does not appear to have been the case. Capitalizing on practices developed during the American administration, canal operations are improving under Panamanian control. Canal Waters Time (CWT), the average time it takes a vessel to navigate the canal, including waiting time, is a key measure of efficiency; according to the ACP, since 2000, it has oscillated between 20 and 30 hours. The accident rate has also not changed appreciably in the past decade, varying between 10 and 30 accidents each year across approximately 14,000 total annual transits. An official accident is one in which a formal investigation is requested and conducted.

Increasing volumes of imports from Asia, which previously landed on U.S. West Coast ports, are now passing through the canal to the American East Coast. The total number of ocean-going transits increased from 11,725 in 2003 to 13,233 in 2007, falling to 12,855 in 2009. (The canal's fiscal year runs from October through September.) This has been coupled with a steady rise in average ship size and in the numbers of Panamax vessels passing through the canal, so that the total tonnage carried rose from 227.9 million PC/UMS tons in fiscal year 1999 to a record high of 312.9 million tons in 2007, falling to 299.1 million tons in 2009. Despite the reduction in total transits due to the negative impact of vessel size (e.g., the inability of large vessels to pass each other in the Gaillard Cut), this represents significant overall growth in canal capacity.

The Panama Canal Authority (ACP) has invested nearly US$1 billion in widening and modernizing the canal, with the aim of increasing capacity by 20%. The ACP cites a number of major improvements, including the widening and straightening of the Gaillard Cut to reduce restrictions on passing vessels, the deepening of the navigational channel in Gatun Lake to reduce draft restrictions and improve water supply, and the deepening of the Atlantic and Pacific entrances to the canal. This is supported by new equipment, such as a new drill barge and suction dredger, and an increase of the tug boat fleet by 20%. In addition, improvements have been made to the canal's operating machinery, including an increased and improved tug locomotive fleet, the replacement of more than 16 km of locomotive track, and new lock machinery controls. Improvements have been made to the traffic management system to allow more efficient control over ships in the canal.

In December 2010, record-breaking rains caused a 17-hour closure of the canal; this was the first closure since the United States invasion of Panama in 1989. The rains also caused an access road to the Centenario bridge to collapse.

Capacity

The canal is currently handling more vessel traffic than had ever been envisioned by its builders. In 1934 it was estimated that the maximum capacity of the canal would be around 80 million tons per year; as noted above, canal traffic in 2009 reached 299.1 million tons of shipping.

To improve capacity, a number of improvements have been imposed on the current canal system. These improvements aim to maximize the possible use of current locking system:

- Implementation of an enhanced locks lighting system;

- Construction of two tie-up stations in Gaillard Cut;

- Widening Gaillard Cut from 192 to 218 metres (630 to 715 ft);

- Improvements to the tugboat fleet;

- Implementation of the carousel lockage system in Gatun locks;

- Development of an improved vessel scheduling system;

- Deepening of Gatun Lake navigational channels from 10.4 to 11.3 metres (34 to 37 ft) PLD;

- Modification of all locks structures to allow an additional draft of about 0.30 metres (0.98 ft);

- Deepening of the Pacific and Atlantic entrances;

- Construction of a new spillway in Gatun, for flood control.

These improvements will enlarge the capacity from 280–90 million PCUMS (2008) to 330–40 PCUMS (2012).

Competition

Despite having enjoyed a privileged position for many years, the canal is increasingly facing competition from other quarters. Because canal tolls are expected to rise, some critics have suggested that the Suez Canal may become a viable alternative for cargo en route from Asia to the U.S. East Coast. The Panama Canal, however, continues to serve more than 144 of the world's trade routes and the majority of canal traffic comes from the "all-water route" from Asia to the U.S. East and Gulf Coasts via the Panama Canal.

The increasing rate of melting of ice in the Arctic Ocean has led to speculation that the Northwest Passage or Arctic Bridge may become viable for commercial shipping at some point in the future. This route would save 9,300 km (5,800 mi) on the route from Asia to Europe compared with the Panama Canal, possibly leading to a diversion of some traffic to that route. However, such a route is beset by unresolved territorial issues and would still hold significant problems owing to ice.

Water issues

Gatun Lake is filled with rainwater, and the lake accumulates excess water during wet months. The water is lost to the oceans at a rate of 101,000 m3 (26,700,000 US gal; 22,200,000 imp gal) per downward lock cycle. Since a ship will have to go upward to Gatun Lake first and then descend, a single passing will cost double the amount; but the same waterflow cycle can be used for another ship passing in the opposite direction. The ship's submerged volume is not relevant to this amount of water. During the dry season, when there is less rainfall, there is also a shortfall of water in Gatun Lake.

As a signatory to the United Nations Global Compact and member of the World Business Council for Sustainable Development, the ACP has developed an environmentally and socially sustainable program for expansion, which will protect the aquatic and terrestrial resources of the canal watershed. After completion, expansion will guarantee the availability and quality of water resources by using water-saving basins at each new lock. These water-saving basins will diminish water loss and preserve freshwater resources along the waterway by reusing water from the basins into the locks. Each lock chamber will have three water-saving basins, which will reuse 60% of the water in each transit. There are a total of nine basins for each of the two lock complexes, and a total of 18 basins for the entire project.

The sea level at the Pacific side is about 20 centimeters (8 inches) higher than that of the Atlantic side due to differences in ocean conditions such as water densities and weather.

Future developments

As demand is rising for efficient global shipping of goods, the canal is positioned to be a significant feature of world shipping for the foreseeable future. However, changes in shipping patterns—particularly the increasing numbers of larger-than-Panamax ships—will necessitate changes to the canal if it is to retain a significant market share. In 2006 it was anticipated that by 2011, 37% of the world's container ships would be too large for the present canal, and hence a failure to expand would result in a significant loss of market share. The maximum sustainable capacity of the present canal, given some relatively minor improvement work, is estimated at 330–40 million PC/UMS tons per year; it was anticipated that this capacity would be reached between 2009 and 2012. Close to 50% of transiting vessels were already using the full width of the locks.

An enlargement scheme similar to the 1939 Third Lock Scheme, to allow for a greater number of transits and the ability to handle larger ships, has been under consideration for some time, has been approved by the government of Panama, and is in progress, with completion expected in 2014. The cost is estimated at US$5.25 billion, and the project will double the canal's capacity, allowing more traffic and the passage of longer and wider ships. This proposal to expand the canal was approved in a national referendum by approximately 80% on October 22, 2006.

Third set of locks project

The current plan is for two new flights of locks to be built parallel to, and operated in addition to, the old locks: one east of the existing Gatun locks, and one southwest of the Miraflores locks, each supported by approach channels. Each flight will ascend from sea level directly to the level of Gatun Lake; the existing two-stage ascent at Miraflores and Pedro Miguel locks will not be replicated. The new lock chambers will feature sliding gates, doubled for safety, and will be 1,400 ft (427 m) long, 180 ft (55 m) wide, and 60 ft (18.3 m) deep. This will allow the transit of vessels with a beam of up to 160 ft (49 m), an overall length of up to 1,200 ft (366 m) and a draft of up to 49 ft (15 m), equivalent to a container ship carrying around 12,000 containers, each 20 feet (6.1 m) in length (TEU).

The new locks will be supported by new approach channels, including a 6.2 km (3.9 mi) channel at Miraflores from the locks to the Gaillard Cut, skirting Miraflores Lake. Each of these channels will be 720 ft (218 m) wide, which will require post-Panamax vessels to navigate the channels in one direction at a time. The Gaillard Cut and the channel through Gatun Lake will be widened to at least 920 ft (280 m) on the straight portions and at least 1,200 ft (366 m) on the bends. The maximum level of Gatun Lake will be raised from 88 ft (26.7 m) to 89 ft (27.1 m).

Each flight of locks will be accompanied by nine water reutilization basins (three per lock chamber), each basin being approximately 230 ft (70 m) wide, 1,400 ft (430 m) long and 18 ft (5.50 m) deep. These gravity-fed basins will allow 60% of the water used in each transit to be reused; the new locks will consequently use 7% less water per transit than each of the existing lock lanes. The deepening of Gatun Lake and the raising of its maximum water level will also provide significant extra water storage capacity. These measures are intended to allow the expanded canal to operate without the construction of new reservoirs.

The estimated cost of the project is US$5.25 billion. The project is designed to allow for an anticipated growth in traffic from 280 million PC/UMS tons in 2005 to nearly 510 million PC/UMS tons in 2025. The expanded canal will have a maximum sustainable capacity of approximately 600 million PC/UMS tons per year. Tolls will continue to be calculated based on vessel tonnage, and will not depend on the locks used.

The new locks are expected to open for traffic in 2015. The present locks, which will be 100 years old by that time, will then be able to give engineers greater access for maintenance, and are projected to continue operating indefinitely. An article in the February 2007 issue of Popular Mechanics magazine describes the plans for the canal, focusing on the engineering aspects of the expansion project. There is also a follow-up article in the February 2010 issue of Popular Mechanics.

On September 3, 2007, thousands of Panamanians stood across from Paraíso Hill in Panama to witness a huge initial explosion and launch of the Expansion Program. The first phase of the project will be dry excavations of the 218 meter (715 ft) wide trench connecting the Gaillard Cut with the Pacific coast, removing 47 million cubic meters of earth and rock. By June 2012, a 30 m reinforced concrete monolith had been completed, the first of 46 such monoliths which will line the new Pacific-side lock walls. By early July 2012, however, it was announced that the canal expansion project had fallen six months behind schedule, leading the expansion to open in April 2015 rather than October 2014, as originally planned.

It was announced in July 2009 that the Belgian dredging company Jan De Nul, together with a consortium of contractors consisting of the Spanish Sacyr Vallehermoso, the Italian Impregilo, and the Panamanian company Grupo Cusa, had been awarded the contract to build the six new locks. The contract will result in $100 million in dredging works over the next few years for the Belgian company and a great deal of work for its construction division. The design of the locks is a carbon copy of the Berendrecht Lock, which is 68m wide and 500m long, making it the largest lock in the world. Completed in 1989 by the Port of Antwerp, which De Nul helped build, the company still has engineers and specialists who were part of that project.

Third bridge

In October 2012, the Panama Canal Authority awarded a contract to The French company Vinci Construction Grands Projets to build a third (permanent) bridge, near the Atlantic side, for a price of US$365,979,472.39. The bridge has no name yet, but Third bridge and Atlantic side bridge are used.

Rival Colombia rail link

China is looking into constructing a 220 km railway between Colombia's Pacific and Caribbean coasts.

Panama Canal Honorary Pilots

During the last one hundred years, the Panama Canal Authority has appointed a few "Panama Canal Honorary Pilots". The most recent of these were Commodore Ronald Warwick, a former Master of the Cunard Line's RMS Queen Mary 2, who has traversed the Canal more than 50 times, and Captain Raffaele Minotauro, Master Senior Grade, of the former Italian governmental navigation company known as the " Italian Line".