T-34

Did you know...

SOS Children, which runs nearly 200 sos schools in the developing world, organised this selection. Sponsoring children helps children in the developing world to learn too.

| T-34 | |

|---|---|

A T-34-85 tank on display at Musée des Blindés in April 2007. |

|

| Type | Medium tank |

| Place of origin | |

| Service history | |

| In service | 1940–present |

| Used by | Soviet Union and 39 others |

| Wars | World War II, and many others |

| Production history | |

| Designer | T-34 Main Design Bureau – KMDB |

| Designed | 1937–1940 |

| Produced | 1940–1958 |

| Number built | 84,070 35,120 T-34 48,950 T-34-85 |

| Specifications (T-34 Model 1941) | |

| Weight | 26.5 tonnes (29.2 short tons; 26.1 long tons) |

| Length | 6.68 m (21 ft 11 in) |

| Width | 3.00 m (9 ft 10 in) |

| Height | 2.45 m (8 ft 0 in) |

| Crew | 4 |

|

|

|

| Armor | Hull front 47 mm /60° (upper part) 45 mm (1.8")/60° (lower part), Hull side 40 mm/41°(upper part), Hull rear 45 mm, Hull top 20 mm, Hull bottom 15 mm; Turret front 60 mm (2.4"), Turret side 52 mm/30°, Turret rear 30 mm, Turret top 16 mm |

| Main armament |

76.2 mm (3.00 in) F-34 tank gun (T-34/85: 85mm gun) |

| Secondary armament |

2 × 7.62 mm (0.308 in) DT machine guns |

| Engine | 12-cyl. 38.8 L diesel model V-2 500 hp (370 kW) |

| Power/weight | 17.5 hp/tonne |

| Suspension | Christie |

| Operational range |

400 km (250 mi) |

| Speed | 53 km/h (33 mph) |

|

|||||

|

||||||||||||||||||||||||||

|

|||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

The T-34 was a Soviet medium tank produced from 1940 to 1958. When it first appeared on the battlefield in 1941, German tank generals von Kleist and Guderian called it "the deadliest tank in the world." It has often been described as the most effective, efficient and influential design of World War II, although its armour and armament were surpassed by later tanks of the era.

First produced at the KhPZ factory in Kharkiv (Ukraine), it was the mainstay of Soviet armoured forces throughout World War II, and widely exported afterwards. It was the most-produced tank of the war, and the second most-produced tank of all time, after its successor, the T-54/55 series. In 1996, T-34 variants were still in service in at least 27 countries.

The T-34 was developed from the BT series of fast tanks and was intended to replace both the BT-5 and BT-7 tanks and the T-26 infantry tank in service. At its introduction, it was the tank with the best balance of firepower, mobility, protection and ruggedness, although its battlefield effectiveness suffered from the unsatisfactory ergonomic layout of its crew compartment, scarcity of radios, and poor tactical employment. The two-man turret-crew arrangement required the commander to aim and fire the gun, an arrangement common to many tanks of the day; this proved to be inferior to three-man (commander, gunner, and loader) turret crews of German Panzer III and Panzer IV tanks. However, according to analysis at the Aberdeen Proving Grounds of a T-34 sent over by the Soviets in 1942, the T-34 had the best optics of any tank so far analyzed there, of either existing tanks or any under development.

The design and construction of the tank were continuously refined during the war to enhance effectiveness and decrease costs, allowing steadily greater numbers of T-34s to be fielded. In early 1944, the improved T-34-85 was introduced, with a more powerful 85 mm gun and a substantially improved three-man turret design with heavier armour. The chassis was employed in the successful SU-85 and SU-100 tank destroyer designs, as well as the SU-122 self-propelled howitzer. By the war's end in 1945, the versatile and cost-effective T-34 had replaced many light and heavy tanks in service, and accounted for the majority of Soviet tank production. Its evolutionary development led directly to the T-54/55 series of tanks, built until 1981 and still operational as of 2013 and which itself led to the T-62, T-72 and T-90 tanks which, along with several Chinese tanks based on the T-55, form the backbone of many of the world's armies even today.

The T-34 was the most important weapon fielded by the Red Army in World War II. Sloping armour increased protection, the V-2 diesel engine used a less flammable fuel, the Christie suspension was fast on rough terrain, and wide tracks gave low ground pressure for good mobility in mud and snow, although reliability and manufacturing issues dogged the wartime production models. The T-34 continued to give the Soviet Army a critical advantage in the war even after its technological advantages had been equalled and surpassed.

Development

In 1939 the most numerous Soviet tank models were the T-26 light tank, and the BT series of fast tanks. The T-26 was a slow-moving infantry tank, designed to keep pace with soldiers on the ground. The BT tanks were cavalry tanks, very fast-moving light tanks, designed for manoeuvre warfare. Both were lightly armoured, proof against small arms but not anti-tank rifles and 37 mm anti-tank guns. During the Battles of Khalkhin Gol, a border war against Japan in 1939, General Zhukov deployed nearly 500 BT-5 and BT-7 tanks against the Imperial Japanese Army (IJA). Although the IJA Type 95 light tanks had diesel engines, the BT tanks did not. Their gasoline engines, commonly used in tank designs by most nations at the time, often burst into flames when hit by IJA tank-killer teams using Molotov cocktails, tank gunfire or "at any other slightest provocation." Both were Soviet developments of foreign designs from the early 1930s; the T-26 was based on the British Vickers 6-Ton, and the BT tanks were based on a design from American engineer Walter Christie. In 1937, the Red Army assigned engineer Mikhail Koshkin to lead a new team to design a replacement for the BT tanks at the Kharkiv Komintern Locomotive Plant (KhPZ). The prototype tank, designated A-20, was specified with 20 mm (0.8 in) of armour, a 45 mm (1.8 in) gun, and the new Model V-2 engine, using less-flammable diesel fuel in a V12 configuration designed by Konstantin Chelpan. It also had an 8×6-wheel convertible drive similar to the BT tank's 8×2, which allowed it to run on wheels without caterpillar tracks. This feature had greatly saved on maintenance and repair of the unreliable tank track of the early 1930s, and allowed tanks to exceed 85 kilometres per hour (53 mph) on roads, but gave no advantage in combat. By then, the designers considered it a waste of space and weight. The A-20 also incorporated previous research (BT-IS and BT-SW-2 projects) into sloped armour: its all-round sloped armour plates were more likely to deflect anti-armour rounds than perpendicular armour.

Koshkin convinced Soviet leader Joseph Stalin to let him develop a second prototype, a more heavily armed and armoured "universal tank" which could replace both the T-26 and the BT tanks. The second prototype Koshkin named A-32, after its 32 mm (1.3 in) of frontal armour. It also had a 76.2 mm (3 in) gun, and the same V-2 diesel. Both were tested in field trials at Kubinka in 1939, with the heavier A-32 proving to be as mobile as the A-20. A still heavier version of the A-32 with 45 mm (1.8 in) of front armour and wider tracks was approved for production as the T-34. Koshkin chose the name after the year 1934 when he began to formulate his ideas about the new tank, and to commemorate the decree expanding the armoured force and the appointment of Sergo Ordzhonikidze to head tank production.

Lessons from Khalkhin Gol regarding armour protection, mobility, welding and main guns were incorporated into the new T-34 tank, and Koshkin's team completed two prototype T-34s in January 1940. In April and May, they underwent a grueling 2,000-kilometre (1,200 mi) drive from Kharkiv to Moscow for a demonstration for the Kremlin leaders, to the Mannerheim Line in Finland, and back to Kharkiv via Minsk and Kiev. Some drivetrain shortcomings were identified and corrected.

Production

Initial production (1940)

| Type | Production (June 1941 – May 1945) |

|---|---|

| Light tanks | 14508 |

| T-34 | 35119 |

| T-34-85 | 29430 |

| KV and KV-85 | 4581 |

| IS | 3854 |

| SU-76 | 12671 |

| SU-85 | 2050 |

| SU-100 | 1675 |

| SU-122 | 1148 |

| SU-152 | 4779 |

Political pressure came from conservative elements in the army to redirect resources into building the older T-26 and BT tanks, or to cancel T-34 production pending completion of the more advanced T-34M design. This political pressure was brought to bear by the developer of the KV-1 and IS-2 tanks which were in competition with the T-34. (Political pressure between designers and factories producing different tanks to meet the same requirements continued much later post-war, including a period when the T-55, T-64, T-72, and T-80 were in concurrent production at several factories, with differing political patrons on the supreme council of the USSR.)

Resistance from the military command and concerns about high production cost were finally overridden by anxieties about the poor performance of Soviet tanks in the Winter War in Finland and the effectiveness of German tanks during the Battle of France. The first production T-34s were completed in September 1940, completely replacing the production of the T-26, BT, and the multi-turreted T-28 medium tank at the KhPZ. Koshkin died of pneumonia at the end of that month (exacerbated by the drive from Kharkiv to Moscow), and the T-34's drivetrain developer, Alexander Morozov, was appointed Chief Designer.

The T-34 posed new challenges for Soviet industry. It had heavier armour than any medium tank produced to that point, and subassemblies originated at several plants: Kharkiv Diesel Factory No. 75 supplied the model V-2 engine, Leningrad Kirovsky Factory (former Putilov works) made the original L-11 gun, and the Dinamo Factory in Moscow produced electrical components. Tanks were initially built at KhPZ No. 183, in early 1941 at the Stalingrad Tractor Factory (STZ), and starting in July shortly after the German invasion at Krasnoye Sormovo Factory No. 112 in Gorky. There were problems with defective armour plates however. Due to a shortage of new V-2 diesel engines, the initial production run from the Gorky factory were equipped with the BT tank's Mikulin M-17 gasoline aircraft engine, and inferior transmission and clutch. Only company commanders' tanks could be fitted with radios, which were expensive and in short supply – the rest signalled with flags. The L-11 gun did not live up to expectations, so the Grabin design bureau at Gorky Factory No. 92 designed a superior F-34 76.2 mm gun (see Designations of Soviet artillery). No bureaucrat would approve production, but Gorky and KhPZ started producing the gun anyway; official permission only came from Stalin's State Defense Committee after troops in the field praised the gun's performance.

Mass production (1941–1943)

After Germany's surprise invasion of the Soviet Union on June 22, 1941 ( Operation Barbarossa), the Wehrmacht's rapid advances forced the evacuation of tank factories to the Ural Mountains, an undertaking of unprecedented scale and haste. KhPZ re-established itself around the Dzherzhinski Ural Railcar Factory in Nizhny Tagil, renamed Stalin Ural Tank Factory No. 183. The Kirovsky Factory, evacuated just weeks before the Germans surrounded Leningrad, moved with the Kharkiv Diesel Factory to the Stalin Tractor Factory in Chelyabinsk, soon to be nicknamed Tankograd ("Tank City"). Voroshilov Tank Factory No. 174 from Leningrad was incorporated into the Ural Factory and the new Omsk Factory No. 174. The Ordzhonikidze Ural Heavy Machine Tool Works (UZTM) in Sverdlovsk absorbed several small factories. While these factories were being moved at record speed, the industrial complex surrounding the Stalingrad Tractor Factory produced forty percent of all T-34s. As the factory became surrounded by heavy fighting in the Battle of Stalingrad in 1942, the situation there grew desperate: manufacturing innovations were necessitated by material shortages, and stories persist that unpainted T-34 tanks were driven out of the factory directly to the battlefields around it. Stalingrad kept up production until September 1942.

Barring this interruption, the only changes allowed on the production lines were to make tank production cheaper and simpler. New methods were developed for automated welding and hardening the plate, including innovations by Prof. Evgeny Paton. The design of the 76.2 mm F-34 gun Model 1941 was reduced from the earlier model's 861 parts to 614. Over two years, the unit production cost was reduced from 269,500 rubles in 1941, to 193,000, and then to 135,000. Production time was cut in half by the end of 1942, even though most experienced factory workers had been sent to the battlefield and replaced by a mixed workforce that included 50% women, 15% boys and 15% invalids and old men. T-34s, which had been "beautifully crafted machines with excellent exterior finish comparable or superior to those in Western Europe or America", were much more roughly finished; this did not compromise the mechanical reliability however.

In 1942 and 1943 the Red Army emphasised rebuilding the losses of 1941 and improving tactical proficiency. The T-34's design was 'frozen'; the rate of production increased rapidly and, typically, design improvements were focused on the production aspect. Soviet designers knew of certain design deficiencies but the desired improvements would have slowed production time. A less cramped hexagonal turret was introduced in 1942, this had been derived from the abandoned T-34M project; subsequently a commander's cupola for all-round vision was added. Limited rubber supplies led to the adoption of steel-rimmed road wheels, and a new clutch was added to the improved five-speed transmission and engine.

Production figures

In 1943, T-34 production had reached an average of 1,300 per month. The T-34 came to symbolise the effectiveness of the Soviet counterattack against the Germans. By the end of 1945, over 57,000 T-34s had been built: 34,780 original T-34 tanks in 1940–44, and another 22,559 T-34-85s in 1944–45. The single largest producer was Factory N.183 (UTZ) building 28,952 T-34s and T-34-85s from 1941 to 1945. The second-largest was Factory N. 112 (Krasnoye Sormovo) in Gorky with 12,604 in the same period.

In 1946, after the war, 2,701 T-34s were built, and large-scale production ceased. It was restarted under licence in Poland (1951–55) and Czechoslovakia (1951–58), where 1,380 and 3,185 T-34-85s were made, respectively, by 1956.. Altogether, as many as 84,070 T-34s are thought to have been built, plus 13,170 self-propelled guns built on T-34 chassis.

Design

Overview

| “ | We had nothing comparable. — Friedrich von Mellenthin (Panzer Battles) | ” |

The initial T-34 version had a 76.2 mm gun, and is often called the T-34/76 (originally a World War II German designation). In 1944, a second major version began production, the T-34-85 (or T-34/85), with a larger turret mounting a larger 85 mm gun. The T-34 had the coil-spring Christie suspension of the BT, using a "slack track" tread system with a rear-mounted drive sprocket and no system of return rollers for the upper run of track, but dispensed with the heavy and ineffective convertible drive. It had well-sloped armour, a relatively powerful engine and wide tracks. Initial 1940 production tanks were installed with the 10-RT 26E radio set, but this was soon replaced by the 9-RS model (also installed on SU-100). From 1953, T-34-85s were installed with the R-113 Granat ("garnet") radio sets.

The T-34, like many other contemporary tanks, required the tank commander to aim and fire the gun while having to coordinate with other tanks and potentially also being a platoon commander. Contemporary German medium tanks (but not light tanks) had three man turret crews that divided the work between commander, gunner and loader. This problem, which had been recognised before the war, was to be corrected with the addition of the upgraded three-man turret on the T-34-85 in 1944. Some tanks also had appliqué armour of varying thickness welded on to the hull and turret. Tanks thus modified were called s ekranami (Russian: с экранами, "with screens").

T-43 project

| “ | The technological pace-setter of World War II tank design. — Steven Zaloga et al. (1997:3) | ” |

After German tanks with the 75 mm (2.95 in) gun were fielded in 1942, Morozov's design bureau began a project to design an advanced T-43, aimed at increasing armour protection while adding modern features like torsion-bar suspension and a three-man turret. The T-43 was intended to be a universal tank to replace both the T-34 and the KV-1 heavy tank, developed in direct competition with the Chelyabinsk heavy tank design bureau's KV-13 project.

In late 1942 the Soviets encountered the new German Tiger I tank and, in July 1943, the Panther tank. Experience at the Battle of Kursk and reports from front-line commanders indicated that the T-34's 76.2 mm gun was now inadequate. An existing 85 mm (3.3 in) anti-aircraft gun was identified as effective against the new German tanks, and could be adapted to tank use. Unfortunately, the T-43 prototype's heavier armour was still not proof against the Tiger's 88 mm gun, and its mobility was found to be inferior to the T-34's, even before installing a heavier 85 mm gun. Although it shared over 70% of its components with the T-34, a commitment to manufacturing it would have required a significant slow-down in production. Consequently, the T-43 was cancelled.

T-34-85

When the T-43 was cancelled, the Soviet command made the difficult decision to retool the factories to produce a new model of T-34 with a turret ring enlarged from 1,425 mm (56 in) to 1,600 mm (63 in), allowing a larger turret to be fitted. The T-43's turret design was hurriedly adapted by V. Kerichev at the Krasnoye Sormovo Factory to fit the T-34. The resulting new T-34-85 tank had a much better gun and finally, a three-man turret with radio (which had previously been in the hull). Now the commander needed only to command the tank, leaving the operation of the gun to the gunner and the loader.

Although a T-34-85 was still not a match for a Panther, the improved firepower made it much more effective than before. The decision to improve the existing design instead of tooling up for a new one allowed the Soviets to manufacture tanks in such numbers that the difference in capabilities could be considered insignificant. In May 1944, the Wehrmacht had only 304 Panthers operating on the Eastern Front, while the Soviets had increased T-34-85 production to 1,200 tanks per month.

Successors

In 1944, pre-war development of a more advanced T-34 tank was resumed, leading to the T-44. The new tank had a turret design based on the T-34-85's, but featured a new hull with torsion-bar suspension and transversely mounted engine; it had a lower profile than the T-34-85 and was simpler to manufacture. Between 150 and 200 of these tanks were built before the end of the war. With substantial drivetrain changes, a new turret, and 100 mm gun, it became the T-54, starting production in 1947.

Operational history

Combat in June–July 1941

| “ | The finest tank in the world. — Field Marshal Paul Ludwig Ewald von Kleist | ” |

The appearance of the T-34 in the summer of 1941 proved a psychological shock to German soldiers, who had expected to face an inferior Soviet enemy. For the most part these expectations were accurate, but the T-34 was a notable exception, superior to any tank the Germans then had in service; the diary of Alfred Jodl seems to express surprise at the appearance of the T-34 in Riga. Initially the Wehrmacht had great difficulty destroying T-34 tanks in combat, as standard German anti-tank weaponry proved ineffective against the T-34's heavy, sloped armour. The high-velocity 76 mm gun was also superior and greatly feared, earning the nickname "Crack-Boom" from German tank crews, reflecting the sound of the gun firing ("crack"), immediately followed by the destruction of its target ("boom"). The Red Army deployed almost 1,000 T-34 tanks, concentrating them into five of their twenty-nine mechanized corps.

One of the first known encounters against a T-34 involved the 17th Panzer Division near the Dniepr River. The T-34 crushed a 37 mm anti-tank gun, destroyed two Panzer IIs, and left nine miles of destruction in its wake before a howitzer destroyed it at close range.

The combat statistics for 1941 show that the Soviets lost an average of over seven tanks for every German tank lost. The Soviets lost a total of 20,500 tanks in 1941, approximately 2,300 of them T-34s and over 900 heavy tanks (mostly KVs).

Within months, the Red Army had lost most of their T-34 and KV tanks, At least half the first summer's total tank losses came about due to mechanical failure, lack of fuel or abandonment rather than direct fire from German tanks or artillery. The Germans' standard 37 mm anti-tank gun proved to be completely ineffective against the T-34, earning the contemptuous nickname "Door Knocker" from German troops; the Germans were forced to deploy 105 mm field guns and 88 mm anti-aircraft guns in a direct fire role to stop them.

Early war combat assessment (1941)

Firepower

The T-34's 76 mm (3 in) gun with anti-tank ammunition was able to penetrate any German tank's armour at normal combat ranges. The F-34 gun firing APCR shell had the capability to penetrate 92 mm of armour at 500m. The best German tanks of 1941, the Panzer 4 Ausf F had 50 mm frontal armour and Panzer III had only 50 mm. This gun also fired an adequate high explosive round.

Mobility

A long road march could be a punishing exercise for a T-34 tank at that time. When in June 1941 D.I. Ryabyshev's 8th Mechanized Corps advanced towards Dubno, the corps lost half of its vehicles. A.V. Bodnar, who was in combat in 1941–42, recalled:

From the point of view of operating them, the German armoured machines were almost perfect, they broke down less often. For the Germans, covering 200 km was nothing, but with T-34s something would have been lost, something would have broken down. The technological equipment of their machines was better, the combat gear was worse.

The Soviet wartime experience is reinforced by US testing at the Aberdeen Proving Grounds regarding the Christie suspension and the tracks:

The Christie's suspension was tested long time ago by the Americans, and unconditionally rejected. On our tanks, as a result of the poor steel on the springs, it very quickly [unclear word] and as a result clearance is noticeably reduced. The deficiencies in our tracks from their viewpoint results from the lightness of their construction. They can easily be damaged by small-calibre and mortar rounds. The pins are extremely poorly tempered and made of a poor steel. As a result, they quickly wear and the track often breaks.

The tracks were the most frequently repaired part. A.V. Maryevski later remembered:

The caterpillars used to break apart even without bullet or shell hits. When earth got stuck between the road wheels, the caterpillar, especially during a turn – strained to such an extent that the pins and tracks themselves couldn't hold out.

Ergonomics and optics

The use of poorly machined, low quality steel side friction clutches and the T-34's outdated and poorly manufactured transmission meant frequent mechanical failure occurred and that they "create an inhuman harshness for the driver". A mallet was also needed to shift gears reducing response times during manoeuvrings. Visibility from the driver's seat was also poor, and they could not see folds in the ground in front of them. As well as the limitations to driver, the T-34/76 had a relatively low and cramped two man turret, with only the commander and loader, also, the gun could not depress more than three degrees with the effect of severely restricting use on a reverse slope or at close range

The loader also had a difficult job due to the lack of a turret basket (a rotating floor that moves as the turret turns), although the same fault was present on all German tanks prior to the Pzkw-IV. The floor under the T-34's turret was made up of ammunition stored in small metal boxes, covered by a rubber mat. There were nine ready rounds of ammunition stowed in racks on the sides of the fighting compartment. Once these initial nine rounds had been used, the crew had to pull additional ammunition out of the floor boxes, leaving the floor littered with open bins and matting and affecting their performance.

The commander fought the tank at a disadvantage; the forward-opening hatch and lack of turret cupola forced him to observe the battlefield through a single vision slit and traversable periscope. German commanders liked to fight "heads-up", with their seat raised and having a full field of view - in the T-34/76 this was impossible. Russian veterans condemned the turret hatches of early models. Nicknamed pirozhok (stuffed bun) because of its characteristic shape, it was heavy and hard to open. The complaints of the crews urged the design group led by A.A. Morozov to switch in August, 1942 to using two hatches in the turret.

The gun sights and range finding for the T-34's 76.2 mm F-34 L/42.5 gun, either the TMFD-7 or the PT4-7, were rather crude, especially compared to those of their German adversaries, affecting accuracy and the ability to engage at long ranges. German soldiers found that the Soviet armour attacked in rigid formations and took little advantage of terrain. As a result of the T-34/76’s two man turret, weak optics and poor vision devices, Germans noted:

T34s operated in a disorganised fashion with little coordination, or else tended to clump together like a hen with its chicks. Individual tank commanders lacked situational awareness due to the poor provision of vision devices and preoccupation with gunnery duties. A tank platoon would seldom be capable of engaging three separate targets, but would tend to focus on a single target selected by the platoon leader. As a result T-34 platoons lost the greater firepower of three independently operating tanks.

The Germans noted the T-34 was very slow to find and engage targets while the Panzers could typically get off three rounds for every one fired by the T-34.

Although in 1941, the T-34 could engage any German tank effectively, it did suffer from certain severe mechanical problems. The US conclusions regarding the mechanical reliably and manufacturing of the 1941 T-34 version tested at the Aberdeen Proving Grounds were as follows:

Judging by samples, Russians when producing tanks pay little attention to careful machining or the finishing and technology of small parts and components, which leads to the loss of the advantage what would otherwise accrue from what on the whole are well designed tanks. Despite the advantages of the use of diesel, the good contours of the tanks, thick armor, good and reliable armaments, the successful design of the tracks etc., Russian tanks are significantly inferior to American tanks in their simplicity of driving, manoeuvrability, the strength of firing (reference to muzzle velocity), speed, the reliability of mechanical construction and the ease of keeping them running.

Communication

A lack of properly installed and shielded radios – if they existed at all – restricted their operational range to under 10 miles. Similarly, the turret drive had poor reliability as suggested by US testing at the Aberdeen proving ground in 1942:

The main weakness [of a two-men turret of T-34 Model 1941] is that it is very tight. The Americans couldn't understand how our tankers could fit inside during a winter, when they wear sheepskin jackets. The electrical mechanism for rotating the turret is very bad. The motor is weak, very overloaded and sparks horribly, as a result of which the device regulating the speed of the rotation burns out, and the teeth of the cogwheels break into pieces. They recommend replace it with a hydraulic or simply manual system.

Armour

The T-34 was one of the most heavily-armoured tanks in the world in 1941. The sloped armour shape provided maximum protection, at the cost of a cramped interior. The armor suffered from build quality issues, especially of plate joins and welds, as well as the use of soft steel combined with shallow surface tempering. All this was noted by US engineers at the Aberdeen Proving Grounds.

In a heavy rain lots of water flows through chinks/cracks, which leads to the disabling of the electrical equipment and even the ammunition.

The following is a war time account of the effectiveness of the T-34's armour and relative impunity, when faced with available German anti-tank guns of the time:

Remarkably enough, one determined 37 mm gun crew reported firing 23 times against a single T-34 tank, only managing to jam the tank’s turret ring.

Although the German anti-tank gun crew managed to score 23 hits, the T-34 referred to did not manage to hit the AT gun once.

Other factors

There was a shortage of repair equipment and recovery vehicles. Other key factors diminishing the initial impact of T-34s on the battlefield were the poor state of leadership, tank tactics, and crew training, a consequence of Stalin's purges of the Soviet officer corps in the late 1930s, aggravated by the loss of the best-trained personnel during the Red Army's disastrous defeats in 1941. Many crews went into combat with only their basic military training plus seventy-two hours of classroom instruction.

The US conclusions regarding the mechanical reliability and manufacturing of the 1941 T-34 version tested at the Aberdeen Proving Grounds were as follows: although in 1941, the T-34 could engage any German tank effectively, it did suffer from certain severe mechanical problems. For example, engines would grind to a halt from dust and sand ingestion as the original "Pomon" air filter was almost totally ineffective and had insufficient air-inflow capacity, starving the combustion chambers of oxygen, lowering compression and thereby restricting the engine from operating at full capacity — this was later partially remedied by the addition of the "Cyclon" filters on later models — and transmission and clutch assemblies were prone to serious mechanical problems.

Further combat assessment (1942–1943)

The Soviets lost 6, 4, 4 and 1.2 tanks for every German tank lost for the years 1942, 1943, 1944 and 1945 respectively.

By 1942 the most common Soviet tank was the T-34. In comparison, the most common German tanks at the time were Panzer III, most armed with the 5cm KwK 38 L/42, (although some were beginning to appear with the more powerful 5cm KwK 39 L/60) and Panzer IV most of which were still armed with the short, low muzzle velocity 7.5cm KwK 37 L/24. Some Panzer IV tanks and StuG III assault guns armed with the longer, higher velocity 7.5 cm KwK 40 L/43 (or the longer L/48 guns) had also begun appearing on the Eastern Front by late 1942. This later gun was capable of destroying a T-34 frontally at around 1,000 metres.

By mid-1942, the T-34 had become vulnerable to improved German weapons and remained so throughout the war, but its armour protection was equal or superior to contemporary tanks such as the M4 Sherman or Panzer IV. During 1942, the Soviets lost 6,600 T-34s out of a total of 15,100 fully tracked AFVs lost. The overall Soviet tank loss ratio for 1942 was similar to that of 1941, but worse for the T-34 — 44% of the tanks lost were T-34s. A study based on Soviet field intelligence reports identified the weapon calibres responsible for T-34/76s destroyed between June 1941 and September 1942.

During the winter of 1941–42, the T-34 again dominated German tanks through its ability to move over deep mud or snow without bogging down; German tanks could not move over terrain the T-34 could handle. The Panzer IV used an inferior leaf-spring suspension and narrow track, and tended to sink in deep mud or snow. Improvements to the T-34 were made throughout production, with a new 5-speed gearbox in 1942, which increased cross-country top speed to 30.5 km/h as well as many individual minor updates.

By 1943, the strategic initiative had generally swung in favour of the Soviets. The Soviets lost 23,500 fully tracked armoured fighting vehicles, including around 14,700 T-34s, a similar (3 to 1) loss ratio to the preceding years.

Introduction of T-34-85 and combat assessment (1944-1945)

As the war went on, the T-34 gradually lost the innovative design advantages it had at the beginning of the German invasion in 1941. By 1943, the 76 mm could not penetrate the Panther's hull front armour and was out-ranged by both the Panther's long 75 mm and the Tiger's 88 mm. In order to restore the technological balance, the Soviets reduced T-34/76 production and moved quickly to manufacture the improved and up-gunned T-34-85, with a new turret and the 85mm M-1944 ZIS-S53 L/51.5 gun. However, even with the introduction of the Soviet 85 mm gun, the upgraded T-34-85 was still not equal in firepower to the Panther or the Tiger: although the T-34-85 could penetrate the armour of its German opponents at up to 500 m (550 yd), the German 88 mm and 75 mm could destroy the T-34-85 at 1,500 m (1,600 yd) or more. The T-34-85 was only able to win battles with substantial numerical superiority, so that enough of the Red Army tanks would survive long enough to close in and penetrate the German tanks' armour, or in situations where they could outflank the German tanks, and hit the thinner flank or rear armour.

As the war progressed, the T-34-85 became an increasingly easy target for the more powerful 75 mm and 88 mm armed tanks; weapons could even pierce the turret relatively easily. The turret armour of the T-34-85, which was cast, was softer than the cold-rolled armour plate of the other parts of the tank and according to one source, it offered poor resistance even to the high-velocity 37 mm shells of automatic AA guns at close range.

The 85 mm ZiS gun of the T-34-85 greatly increased firepower over the previous 76.2 mm F-34 cannon on the T-34/76. The length of the 85 mm gun barrel (4.645 meters) made it necessary for crews to be careful not to dig it into the ground on bumpy roads or in combat; A.K. Rodkin commented: "the tank could have dug the ground with it in the smallest ditch. If you fired it after that, the barrel would open up at the end like the petals of a flower."

At the start of the war, the T-34 represented about 4% of the Soviet tank arsenal; but by the end it comprised at least 55% of tank production (based on figures from Zaloga; Zheltov 2001 lists even larger numbers). By the time the T-34 had replaced older models and became available in greater numbers, newer German tanks, including the improved Panzer V "Panther", outperformed it. The T-34-85 tank initially cost about 30% more to produce than a Model 1943, at 164,000 rubles; by 1945 this had reduced to 142,000 rubles. During the course of the Great Patriotic War the cost of a T-34 tank reduced by almost half, from 270,000 rubles in 1941, while in the meantime its top speed remained about the same, and its main gun's armour-penetration and turret frontal-armour thickness both nearly doubled.

During the last years of the war the Soviets' improving tactics were still inferior to the Germans', but the Red Army's growing operational and strategic skill and its larger inventory of tanks helped bring the loss ratios down. The T-34-85 in early 1944 did give the Red Army a tank with a better gun and turret, while its armour and mobility were arguably better than German Panzer IV and Sturmgeschütz III; it could not match the Panther's armour or its 7.5 cm KwK 42 gun. To the Soviet advantage, there were far fewer Panthers (or German AFVs in general) than T-34s.

Comparisons can be drawn between the T-34 and the U.S. M4 Sherman tank. Both tanks were the backbone of the armoured units in their respective armies, and both were upgraded extensively and fitted with more powerful guns. Both were designed for ease of manufacture and maintenance, sacrificing some performance for this goal. Neither were equal to Germany's heavy tanks, the Tiger and Panther. The improved T-34-85 remained the standard Soviet medium tank with an uninterrupted production run until the end of the war. The Germans responded to the T-34 by introducing the new, powerful and initially failure-prone Panther tank, while also improving the firepower of the numerous older Panzer IV tanks and StuG III self-propelled guns. The emphasis on quality during tank production allowed the Soviets to maintain a substantial numerical superiority in tanks throughout the war. Production figures for all Panther types reached no more than 6,557, and for the expensive heavy Tiger 2,027. Production figures for the T-34-85 alone reached 22,559; eventually, the T-34 replaced most light, medium, and heavy tanks in Soviet service.

By 1944 the Soviets had the absolute strategic initiative, with massive numerical superiority, and in terms of supply distribution and logistics, also operational superiority. They had the luxury of being able to concentrate large armoured forces at any points on the front they desired, while still being able to strongly defend everywhere. The Soviets also attained critical air superiority for the first time, albeit not always and not everywhere. However, in 1944 the Soviets lost 23,700 fully tracked AFVs (only 2,200 of which were light tanks): this was the highest number of AFV losses in a single year by any country in history. Of these 58% were T-34s, the majority of those being the new up-gunned and improved T-34-85s. Despite having the operational and strategic advantage Soviet losses were about 4 tanks for every German tank destroyed.

Conclusions

The impression that it made was to influence greatly subsequent tank development throughout the world— John Milsom (1971)

Soviet fully tracked AFV production from June 1941 to May 1945 was 99,150 (this includes all types of fully tracked assault and self-propelled guns) vehicles. An additional 11,900 tanks and self-propelled guns were received via Lend Lease. In comparison, the Germans, who are often criticised for producing too few, albeit higher quality tanks replete with too many refinements and excessive quality control during production, produced a total of 26,925 tanks, 612 command tanks, 232 flame tanks, 10,550 assault guns, 7,831 tank destroyers, and 3,738 assault and self-propelled artillery AFVs for a combined total of around 49,900 fully tracked AFVs between 1938 and May 1945. Soviet tanks had a generally rough and ready finish, and lacked many ergonomic and refinement features which were deemed essential by German and to a large extent by Allied tankers as well. That there were more Soviet tanks produced during the war than were destroyed (approximately 44,900 of the 55,550 T-34s produced were lost), regardless of the individual tactical performance of each, ultimately helped to win the war. The Soviets mass-produced more fully tracked AFVs, and more T-34s in particular than the Germans did total fully tracked AFVs. It can be argued that it was exactly the emphasis on refinements, manufacturing quality and subtleties of design which gave German tank crews significant edge in combat at the tactical level. The Soviets achieved strategic success, but paid an exceptionally high price; approximately 44,900 of the T-34s were lost out of a total of 96,500 fully tracked AFVs lost compared with only 32,800 for the Germans (this includes all SP guns, SP artillery, and several thousand vehicles captured when Germany surrendered on the East Front) during all of World War II; a global loss ratio of 2.94 to 1 in favour of the Germans.

Korean War (1950–1951)

Many Soviet-client and former Soviet-client states used T-34-85s after the end of World War II. A full brigade equipped with about 120 North Korean T-34-85s spearheaded the invasion of South Korea in June 1950. Additional T-34 tanks later joined the first assault force after it had penetrated into South Korea. The North Korean tanks had overwhelming early successes against South Korean infantry, Task Force Smith and U.S. M24 Chaffee light tanks. The World War II-era 2.36-inch bazookas used by the Americans were useless against the T-34s, as were the 75 mm cannons of the M24 Chaffee.

The North Korean T-34s lost their momentum when they encountered U.S. M26 heavy tanks and ground-attack aircraft, and when the U.S. infantry upgraded their antitank weapons to 3.5-inch Super Bazookas hurriedly airlifted from the United States. The M4 Sherman (M4A3E8 model) and British tanks such as the Centurion, Churchill, and Cromwell also entered the war. The tide turned in favour of the United Nations forces in August 1950, when the North Koreans suffered major tank losses during a series of battles in which their foes brought their newer equipment to bear. The U.S. landings at Inchon on September 15 cut off the North Korean supply lines, causing their armoured forces and infantry to run out of fuel, ammunition and other supplies. As a result, the North Koreans had to retreat, and many T-34s and heavy weapons were abandoned. By the time the North Koreans had fled from the South, a total of 239 T-34s and 74 SU-76s had been lost. After November 1950, North Korean armour was rarely encountered.

A few more tank engagements occurred when China entered the conflict in February 1951 with four regiments of tanks (a mix of mostly T-34-85 tanks, a few IS-2 tanks, and other AFVs). However, because these tanks were dispersed with the infantry, tank to tank battles with UN forces were uncommon. China produced T-34 tanks under the designation Type 58, though production soon stopped when the Type 59 became available. At least one T-34 has also been spotted in China, converted into a fire-fighting vehicle.

A 1954 survey concluded that there were in all 119 tank vs. tank actions involving U.S. Army and Marine units during the Korean War, with 97 T-34-85 tanks knocked out and another 18 probable. The M4A3E8 was involved in 50% of the tank actions, the M26 in 32%, and the M46 in 10%. The M26 and M46 proved to be an overmatch for the T-34-85 as their 90 mm HVAP round could punch all the way through the T-34 from the front glacis armour to the back, whereas the T-34-85 had difficulty penetrating the armour of the M26 or the M46. The M4A3E8, firing 76 mm HVAP rounds, was a closer match to the T-34-85 as both tanks could destroy each other at normal combat ranges; however, the HVAP round gave the M4A3E8 an advantage in penetration.

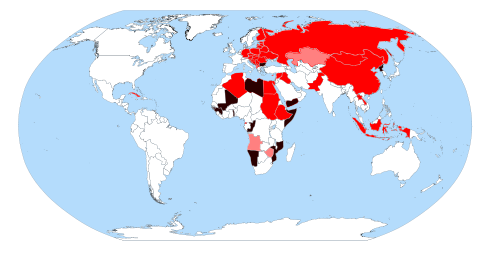

Operators

After World War II, the following countries used the T-34. As of 1996, it remained in service in 27 of those countries, indicated by asterisks (*).

|

Africa |

Current and past military operators

As of 2012, the T-34 is mostly in reserve, or treated as an infantry backup. However, in some countries, is also considered as a second or main tank, because of the lack of more modern tanks.

Use in other countries

The Soviet and Finnish Army used T-34s until the 1960s, the former included the 76.2mm gun armed versions until at least 1968 when they were used in filming the sequel to the film The Living and the Dead. The Finnish tanks were captured from the attacking Soviets or trophies purchased from Germany. Many of the Т-34-85s were enhanced with Finnish or Western equipment, such as improved optics.

T-34s equipped many of the Eastern European (later Warsaw Pact) armies. They served in the suppression of the East German uprising of June 17, 1953, as well as of the Hungarian uprising in 1956. They were also used in the Middle East, the Vietnam War, and even as recently as the Bosnian War. In May 1995, a Serb T-34 attacked an UNPROFOR outpost manned by the 21st Regiment of the Royal Engineers in Bosnia, injuring a British peacekeeper. Croatia inherited 25 or 30 from Yugoslavia but has since withdrawn them from service. T-34s were sporadically available in Afghanistan (it is not known if T-34s were used against coalition troops), and Saddam Hussein had T-34s in the Iraqi army in the early 1990s. Several African states, including Angola and Somalia, have employed T-34-85s in recent years. Cuban T-34-85s also saw action in Africa.

Cypriot National Guard forces equipped with some 35 T-34-85 tanks helped to enforce a coup by the Greek junta against democratically elected President Archbishop Makarios on July 15, 1974. They also saw extensive action against Turkish forces during the Turkish invasion in July and August 1974, with two major actions at Kioneli and at Kyrenia on July 20, 1974.

Symbolism

A T-34-85 tank monument in the East German city of Karl-Marx-Stadt ( Chemnitz) was the target of a 1980 bomb attack that inflicted minor damage on the vehicle and blew out nearby windows. The bomber, Josef Kneifel, was sentenced to life imprisonment in Bautzen, but was released after a deal with the West German government in 1987. After German unification in 1990, the tank was transferred to a museum in Ingolstadt.

Another such tank, mounted atop the monument to Soviet tank crews in Prague, was the focus of significant controversy. The monument, also known locally as 'Saint Tank,' intended to represent Lt I.G. Goncharenko's T-34-85, the first Soviet tank to enter Prague in May 1945, actually bore an IS-2m heavy tank. To many in Prague, the tank was also a reminder of the Soviet invasion which ended the Prague Spring of 1968. The tank was painted pink by artist David Černý in 1991. Following an official protest from the Russian government, the arrest of Černý, a coat of official green paint, public demonstrations, and a further coat of pink paint applied by fifteen parliamentary deputies, the tank was finally removed to a military museum.

Four Tankers and a Dog ( Czterej pancerni i pies) was a very successful war-themed Polish television series of the 1960s (based on an eponymous novel by a Polish writer Janusz Przymanowski (1922–98), himself a Red Army volunteer) which made T-34 tank number 102 an icon of Polish popular culture. It was also shown in other Soviet-bloc countries where it was also well received, surprisingly even in the German Democratic Republic (East Germany). At the beginning of the 21st century reruns of the black and white series still manage to attract a large audience.

In Budapest on 23 October 2006, the 2006 protests in Hungary climaxed during the official 50th anniversary of the 1956 Hungarian Revolution. Protesters managed to start an unarmed T-34 tank which was part of a memorial exhibition, and used it in riots against police forces. The tank drove a few hundred metres, then stopped in front of the police, causing no personal injury.

Variants

Identification of T-34 variants can be complicated. Turret castings, superficial details and equipment all differed between factories. New features were added in the middle of production runs or retrofitted to older tanks. Knocked-out tanks were rebuilt, sometimes incorporating newer-model equipment and even new turrets.

The Red Army never had a consistent policy for naming the production models. Since at least the 1980s however, many academic sources (notably, AFV expert Steven Zaloga) have used Soviet-style nomenclature: T-34 and T-34-85, with minor models distinguished by year, as T-34 Model 1940. Some Russian historians use different names: they refer to the first T-34 as the T-34 Model 1939 instead of 1940, all T-34s with the original turret and F-34 gun as Model 1941 instead of Models 1941 and 1942, and hexagonal-turret T-34 as Model 1942 instead of 1943.

German military intelligence in World War II referred to the two main production models as T-34/76 and T-34/85, with minor models receiving letter designations such as T-34/76A—this nomenclature has been widely used in the West, especially in popular literature. When the German Wehrmacht used captured T-34s, it designated them Panzerkampfwagen T-34(r), where the "r" stood for russisch ("Russian").

The Finns referred to the T-34 as the Sotka, after the Common Goldeneye, a sea duck, because the side silhouette of the tank resembles a swimming waterfowl (as related in the memoirs of Finnish tank ace Lauri Heino). The T-34-85 was called pitkäputkinen Sotka ("long-barreled Sotka").

The T-34 (German designation: T-34/76) was the original tank with a 76.2 mm gun.

- Model 1940 (T-34/76A): Early production run with interim L-11 76.2 mm tank gun in a two-man turret.

- Model 1941 (T-34/76B): Main production with heavier armour and the superior F-34 76.2 mm gun.

- Model 1942 (T-34/76C): Many minor manufacturing improvements.

- Model 1943 (T-34/76D, E, and F): New cast hexagonal turret, nicknamed "Mickey Mouse" by the Germans because of its appearance with the twin, round turret-roof hatches open. Main production had a new commander's cupola.

- T-34/57: Fewer than 324 T-34s in 1941 and 1943–44 were fitted with the ZiS-4 or the ZIS-4M high-velocity 57 mm gun to be used as tank hunters. Some of them took part in the Battle of Moscow.

The T-34-85 (T-34/85) was a major improvement with a three-man turret and long 85 mm gun.

- Model 1943: Short production run of February–March 1944 with D-5T 85 mm gun

- Model 1944: Main production, with simpler ZiS-S-53 85 mm gun, radio moved from the hull into a turret with improved layout and new gunner's sight

All T-34-85 models are externally very similar. Various technical improvements continued to be made to the T-34-85, including major refurbishing programs in 1960 and 1969. One can recognise the widely exported Czechoslovakian-built T-34-85s by a semi-conical armoured fairing (like a rear-facing scoop) on the left rear slanting side-panel of the engine compartment sponson.

| T-34 Model 1940 |

T-34 Model 1941 |

T-34 Model 1942 |

T-34 Model 1943 |

T-43 prototype |

T-34-85 | T-44 | |

|---|---|---|---|---|---|---|---|

| Weight | 26 t | 26.5 t | 28.5 t | 30.9 t | 34 t | 32 t | 31.9 t |

| Gun | 76.2 mm L-11 | 76.2 mm F-34 | 76.2 mm F-34 | 76.2 mm F-34 | 76.2 mm F-34 | 85 mm ZiS-S-53 | 85 mm ZiS-S-53 |

| Ammunition | 76 rounds | 77 rounds | 77 rounds | 100 rounds | 60 rounds | 58 rounds | |

| Fuel | 460 L (120 U.S. gal) |

460 L (120 U.S. gal) |

610 L (160 U.S. gal) |

790 L (210 U.S. gal) |

810 L (215 U.S. gal) |

642 L (170 U.S. gal) |

|

| Road range | 300 km (185 mi) | 400 km (250 mi) | 400 km (250 mi) | 465 km (290 mi) | 300 km (185 mi) | 360 km (225 mi) | 300 km (185 mi) |

| Armour | 15–45 mm (0.60–1.8 in) |

20–52 mm (0.8–2.1 in) |

20–65 mm (0.8–2.6 in) |

20–70 mm (0.8–2.8 in) |

16–90 mm (0.6–3.5 in) |

20–90 mm (0.8–3.5 in) |

15–120 mm (0.6–4.7 in) |

| Cost | 270,000 rubles | 193,000 rubles | 135,000 rubles | 164,000 rubles | |||

| Notes: dimensions, road speed, engine horsepower did not vary significantly, except for the T-43 which was slower than the T-34. | |||||||

Other armoured fighting vehicles

- Flame-thrower tanks: OT-34 and OT-34-85 had an internally mounted flamethrower ATO-41 (ATO-42 later) replacing the hull machine-gun.

- PT-1 T-34-76: Protivominniy Tral (counter-mine trawl) Mine roller tank, mostly built on T-34 Model 1943 or T-34-85 chassis

- Self-propelled guns and tank destroyers:

Surviving vehicles

Partly due to the large number produced, there are hundreds of surviving T-34s. Examples of this tank are in the collections of most significant military museums, and hundreds more serve as war memorials. Many are in private ownership, and demilitarised working tanks change hands for US$20,000–40,000. Some still may serve in a second-line capacity in a number of Third World militaries, while others may find use in a civilian capacity, primarily in film making. In many World War II films, such as Saving Private Ryan, The Battle of Neretva, and Kelly's Heroes, T-34-85 tanks were modified to resemble Tiger I tanks, due to the rarity of the latter vehicle.

In 2000, a T-34 Model 1943 was recovered that had spent 56 years at the bottom of a bog in Estonia. The tank had been captured and used by retreating German troops, who dumped it in the swamp when it ran out of fuel. The anaerobic environment of the bog preserved the tank and ensured there were no signs of oil leakage, rust, or other significant water damage. The engine was restored to full working order.

Other significant surviving T-34s include a Model 1941 at the U.S. Army Ordnance Museum in Aberdeen, Maryland—one of the oldest surviving vehicles. Other older 76 mm-armed T-34s have recently been recovered from old battle sites. The French Musee des Blindes at Saumur holds two T-34s including one in full working condition that is displayed in action at their summer "Carrousel" live tank exhibition. The Mandela Way T-34 Tank, a privately–owned T-34-85 named after the street it is sited in near Bermondsey, London, is frequently repainted by artists and graffitists.